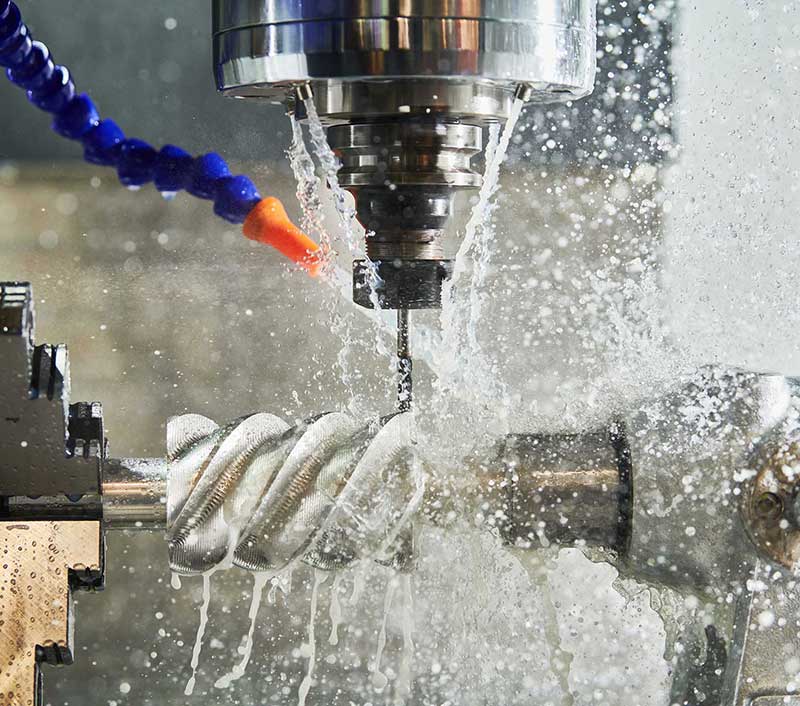

Improve air quality with MistBuster® smoke and mist extraction

Indoor Air Quality Solutions for Machining Applications

A BREATH OF FRESH AIR

CNC oil mist extraction that works

At Brown & Holmes (Tamworth) Ltd our goal is to tailor an indoor air cleaning system that provides solutions for your machining application problems. Our systems deliver these benefits:

- Protect employees by reducing exposure to hazardous airborne mist, smoke and metal particles produced by industrial machining applications.1

- Comply with indoor air quality standards and governmental regulations.

- Protect equipment.

- Reduce maintenance and operation costs.

- Meet employee and customer expectations for a clean, healthy and safe working environment.

- Improve employee retention and recruitment.

A BREATH OF FRESH AIR

Highly efficient capture of harmful airborne contaminants

Air Quality Engineering, Inc. designs and manufactures the MistBuster® family of industrial mist extraction systems for the source capture of mist and smoke generated by today’s machine tools.

The MistBuster® product line is highly efficient at collecting and removing dangerous airborne CNC machining application contaminants using electrostatic precipitation and/or media filtration technologies. Options include: disposable high efficiency particulate air (HEPA) filters; extended service filter (ESF) media filters; and carbon modules for enhanced filtration and odor control.

Get in touch today

Contact us for Quote

“Many thanks to all involved at Mist buster. The sales team offered clear, personable advice on a suitable product, along with prompt delivery. Instillation was simple and hassle free. The Mist buster has made a dramatic change to our working environment and we would highly recommend”.

We have our Mist buster filtration units serviced Bi – annually by Brown & Holmes, we opted to buy additional electro static plates which are stored at Brown & Holmes and their service technicians bring the clean ones to site & exchange the units over & take the dirty ones back for cleaning. This way we have minimum disruption on site and this works perfect for our business as the whole unit is checked out that it working to its capacity.

A BREATH OF FRESH AIR

Oil and mist extraction news & case studies

HSE rolls out inspections of CNC machining works.

The HSE are clamping down on metalwork manufacturers who are still not complying with COSHH regulations (Control of Hazardous Substances Hazardous to Health Regulations 2002) by rolling out an inspection campaign.

Nissan reduce smoke and mist extraction costs

Wanting to eradicate the smoke and mist created on their CNC machines during production, Nissan Motor Corporation recently installed MistBuster850 units from Brown and Holmes into their plant at Sunderland

Brown and Holmes install MB500 on a Hurco VM10

Following up on a website enquiry a new customer to Brown and Holmes from Aylesbury requested extraction on his new Hurco VM10.