A BREATH OF FRESH AIR

Extraction and filtration of smoke, oil and coolant mist

The MistBuster® family of products is designed for the generated in CNC machining mist extraction applications. Our goal is to tailor an indoor air cleaning system that provides solutions for your machining applications. MistBuster® deliver the following benefits:

- Protect employees by reducing exposure to hazardous airborne mist, smoke and metal particles produced by industrial machining applications.

- Comply with indoor air quality standards and governmental regulations set out by the HSE.

- Protect equipment

- Reduce maintenance and operation costs

- Meet employee and customer expectations for clean, healthy and safe working environment

- Improve employee retention and recruitment

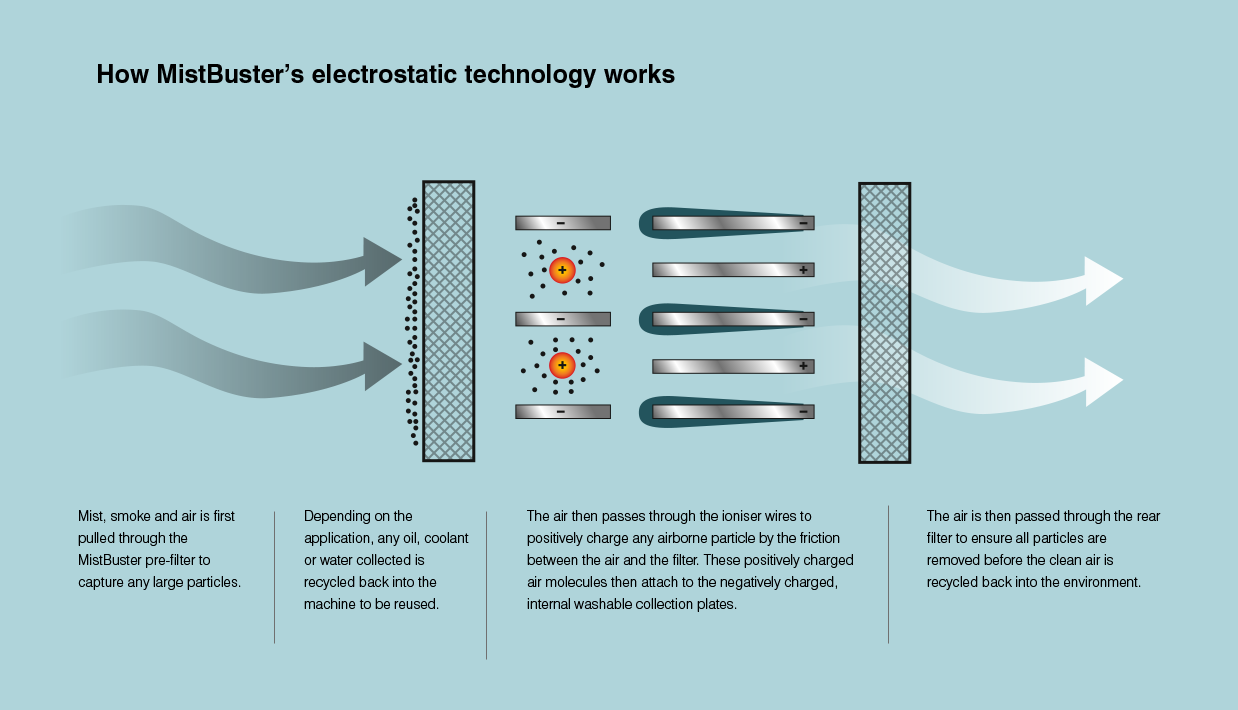

Electrostatic filtration technology

The MistBuster® uses electrostatic filtration technology, electronic air filter systems use one or more permanent electronic collector cells or filters featuring electrostatic precipitation technology to collect and remove airborne mist, smoke and metal particles generated by machining applications. An electronic collector cell is composed of an ionizing or charging section. Incoming contaminant particles pass through an intense ionization field in the charging section. The ionization causes the particles to lose electrons and a acquire a positive electrical charge.

The collection section, positive-charged metal plates or fins repel the positively charged particles and alternating grounded fins attract the positively charged particles that coalesce and form droplets. Contaminated droplets remain trapped on the grounded fins until the collector cell is washed.

The MistBuster® product line is highly effective at collecting and removing dangerous airborne machining application contaminants using electrostatic precipitation and /or media filtration technologies. Operations include: disposable high efficiency particulate air (HEPA) filters: extended service filter (ESF) media filters: and carbon modules for enhanced filtration and odour control.

More up-time and less maintenance.

Investment in metallurgy research resulted in the creation of a state of the art ionization wire alloy that minimizes breakage and still achieves excellent ionization. This proprietary alloy and design has greatly reduced the need to replace ionization wires. The MistBuster® product has been carefully designed to minimise vibration. Dynamically balanced impellers mounted on rubber isolation mounts mitigates to the possibility of transmitting vibration to your machine tool, protecting the integrity of your precision tolerances. The current generation of MistBuster® electrostatic units use patented “floating contact” design and “air breaks” on contact boards to provide a more robust solution to the problem of short circuits due to coolant tracking. This means more up-time and less maintenance.

MistBuster® patented coolant selector switch easily adjusts the high-voltage used with it’s collector cells to compensate for varying dielectric qualities of coolants and oils.

With a variety of mounting options, model sizes and available configurations, there is sure to be a MistBuster® solution that will meet your specific requirements.